LOGICDATA AND DEWESOFT

Precision and efficiency are critical to delivering high-performance actuator systems and other integrated mechatronic solutions: minimizing waste, improving user experience, and ensuring that customers receive ultimate value for money.

Reliable data is at the heart of the push for efficiency in mechatronics, which is why LOGICDATA has partnered with Dewesoft to take performance testing to the next level. This collaboration has resulted in cutting-edge test benches, which integrate Dewesoft’s advanced data acquisition (DAQ) systems into LOGICDATA’s in-house development processes for brushless motors and linear actuators. This allows for precise analysis and optimization of actuator performance, resulting in superior mechatronic technology for LOGICDATA customers.

LOGICDATA and Dewesoft: Unlocking New Levels of Efficiency

The market for mechatronic systems shows an increasing demand for energy-efficient and high-performance actuators. To work effectively toward these goals, it is essential for mechatronic developers like LOGICDATA to understand the complete power flow within the system. Crucially, the relationship between power in- and output, which is where the Dewesoft partnership comes into play.

As part of its motor development competence, LOGICDATA specializes in small electric motors, for example customized brushless DC motors and servo motors, for specific operating points. The integration of Dewesoft’s test solutions within the design and development processes allows LOGICDATA to analyze the efficiency of each individual component, helping to minimize power losses and maximize output.

“For us, it is imperative to analyze the efficiencies of every single sub-system of the whole power chain to know all power losses and thus identify optimization potential. This focus on continuous improvement shows LOGICDATA’s commitment to innovation, ensuring that every product meets the highest standards of performance and durability.”

Universal Testing Systems: the Core of the Partnership

Increasing efficiency within systems and individual mechatronic components is traditionally extremely time-consuming, requiring lengthy measurement setups that have a high risk of errors due to their complexity. Likewise, localizing the exact source of any inefficiency can be demanding without the required analytics tools for detailed insights.

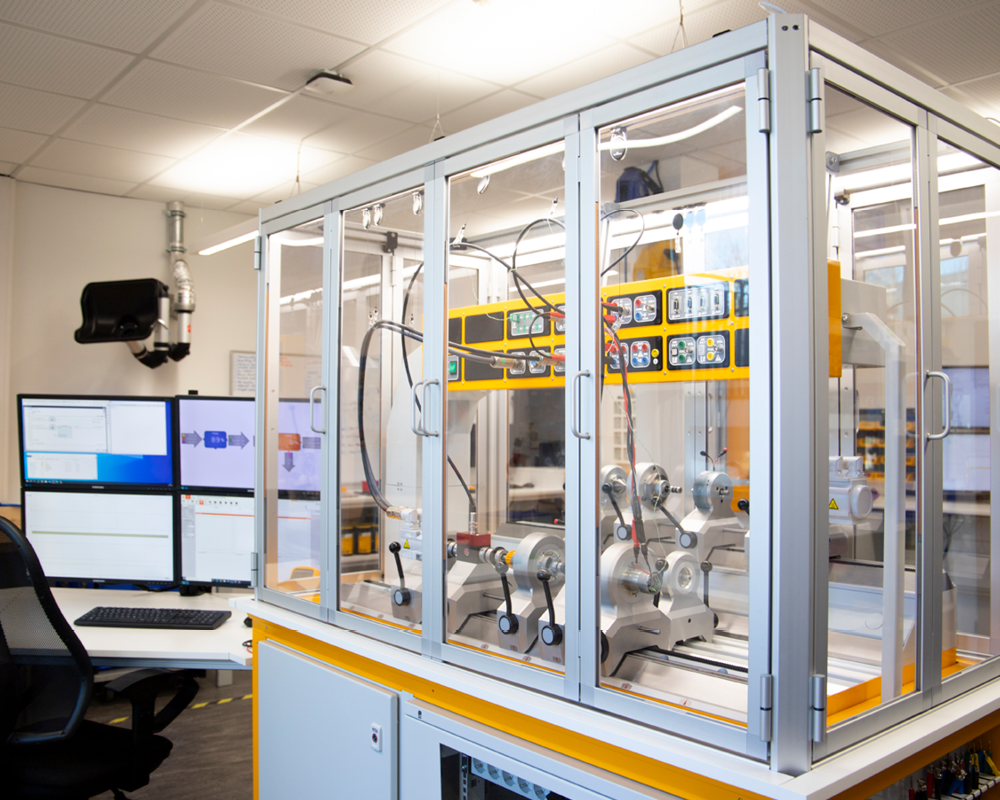

Together, LOGICDATA and Dewesoft decided to work on a series of solutions to improve the accuracy of mechatronic system testing while dramatically reducing set-up times. By developing test benches that are customized precisely for the testing of LOGICDATA components, our in-house experts have been able to optimize performance more effectively.

One such example is LOGICDATA’s test bench, which was designed to test numerous variants of different mechatronic systems, such as motors, brakes, gear boxes, and even entire drive chains. The use of a slide rail system makes mounting and demounting the devices under test faster and more intuitive. In addition, the pluggable connection of all electric signals via the cable interface provides a clear overview of the wiring structure. This has dramatically reduced testing times and enabled LOGICDATA’s engineers to locate and rectify inefficiencies faster, leading to shorter iteration cycles in development.

About Dewesoft

Dewesoft develops innovative measurement solutions that simplify complex data analysis and drive technological progress. By challenging industry standards and focusing on customer needs, Dewesoft provides cutting-edge equipment used by leading global brands to advance efficiency and performance in various industries.

LOGICDATA’s In-House Testing Lab

LOGICDATA’s in-house testing lab enables precise performance evaluation at every stage of development, from initial design to quality assurance. The lab supports flexible testing configurations for motors, brakes, gearboxes, drive systems, and inline actuators. Automated test sequences and real-time data analysis ensure efficient optimization and long-term reliability of mechatronic components.

Clear, Actionable Data for Mechatronic Optimization

Dewesoft’s hardware is integrated into the test benches. The measured data is processed by DewesoftX, a data acquisition and signal processing software that visualizes test results into reports. For example, during actuator testing, current, voltage, and mechanical variables such as force, torque and velocity are measured, helping to determine power flow and efficiency.

“The collaboration between LOGICDATA and Dewesoft shows the value of advanced measurement technologies in driving product development forward. By combining LOGICDATA’s expertise in actuator design with Dewesoft’s industry-leading DAQ systems, the path to smart, efficient mechatronic solutions is clear.”

Meeting Industry Standards for Efficiency

As energy efficiency and performance expectations continue to rise, rigorous testing and validation have become essential processes in motor development. By integrating advanced measurement technology, LOGICDATA ensures that every product meets strict industry standards while maximizing reliability and efficiency.

The partnership with Dewesoft not only strengthens LOGICDATA’s ability to deliver high-quality products but also sets new industry benchmarks for actuator testing and validation. With precision engineering and data-driven insights at the core of their development process, LOGICDATA continues to push the boundaries of innovation in the adjustable furniture and automation industries.

Article in Short

- Data-Driven Performance Testing. LOGICDATA partners with Dewesoft to enhance actuator and motor testing, integrating advanced data acquisition (DAQ) systems for precise analysis and optimization.

- Optimizing Efficiency. Custom test benches allow for detailed power flow analysis, helping LOGICDATA minimize energy losses and maximize motor output.

- Faster, More Accurate Development. Universal test systems streamline testing processes, reducing iteration cycles and improving product performance.

- Advanced Measurement Technology: DewesoftX software provides real-time insights, including thermal imaging, to identify inefficiencies and enhance product durability.